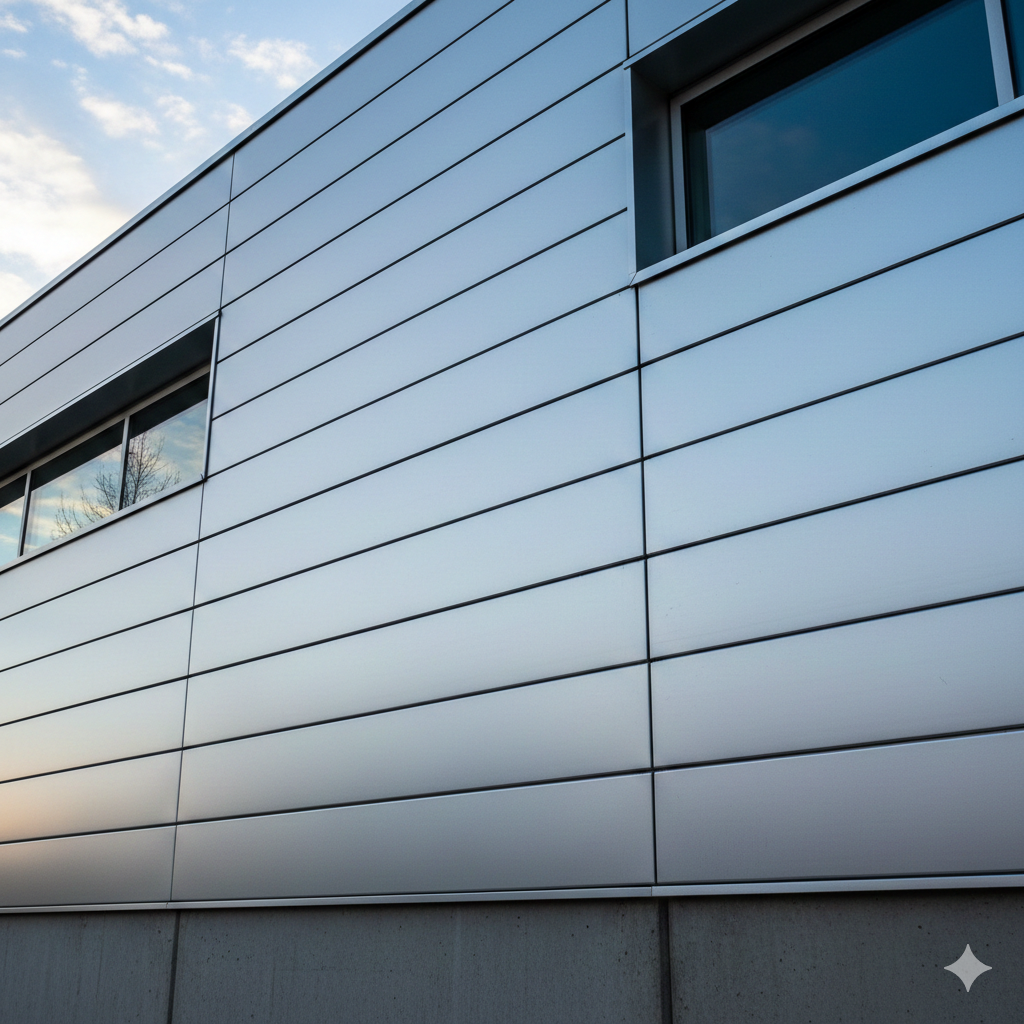

An aluminum cladding supplier specializes in providing high-quality aluminum materials designed for exterior and interior building applications. These suppliers offer products that combine durability, weather resistance, and aesthetic appeal to enhance the longevity and appearance of structures. They ensure that customers receive materials that meet industry standards for performance and sustainability, often including options with advanced features like fire retardance and thermal insulation.

Choosing the right aluminum cladding supplier involves considering factors such as product variety, quality certifications, and the supplier’s ability to deliver customized solutions. Many suppliers serve both residential and commercial markets, offering panels, siding, and systems that fit a range of architectural needs. Their products emphasize low maintenance and energy efficiency, making them a practical choice for modern construction.

Companies in this sector often provide environmentally sustainable options, using recyclable aluminum to minimize the carbon footprint of cladding projects. In regions like Canada and the US, suppliers balance innovation with compliance to local codes, ensuring their aluminum cladding meets regional requirements. This combination of design flexibility and durability solidifies their role in contemporary building projects.

Choosing an Aluminum Cladding Supplier

Selecting the right aluminum cladding suppliers require attention to specific qualities, the range of products offered, adherence to industry standards, and cost considerations. These factors shape the supplier’s ability to meet project demands effectively and ensure long-term performance.

Key Qualities to Look For

A reputable supplier should demonstrate extensive experience in aluminum cladding and maintain a track record of delivering quality products. Reliability in lead times and consistent communication are critical to avoid project delays.

Technical expertise is essential. Suppliers who understand different aluminum alloys, finishes, and installation requirements provide valuable guidance. They should offer detailed product information, including material thickness and coating types.

Customer service matters. A supplier willing to provide samples, technical support, and post-sale assistance enhances project confidence. Lastly, consider whether the supplier can handle custom orders and adapt to unique architectural needs.

Types of Aluminum Cladding Offered

The product range usually includes aluminum composite panels (ACPs), solid aluminum sheets, and pre-finished cladding options. ACPs combine aluminum skins with a core material, offering lightweight durability and design flexibility.

Finishes vary from mill-finished and anodized to PVDF or polyester coatings. These influence weather resistance, color retention, and maintenance levels. A good supplier provides these choices to suit different environmental conditions.

Some also specialize in innovative or proprietary systems for both exterior and interior applications. Availability of fire-resistant or insulated panels may be important depending on building codes and project scope.

Certifications and Standards

Compliance with industry standards such as ASTM, EN, or ISO is vital. It verifies that the aluminum cladding meets performance and safety criteria.

Look for suppliers whose products are tested for weather resistance, fire safety, and structural integrity. Certifications from recognized bodies provide assurance of quality and durability.

Environmental standards like LEED compatibility or recycled content can also be relevant, especially for sustainable construction projects. Documentation and transparent quality control processes are indicators of a trustworthy supplier.

Comparing Supplier Pricing

Price differences often reflect variations in material quality, finish type, and panel thickness. Be cautious of unusually low bids that may compromise durability or service.

Evaluate the total cost, including delivery charges, customization fees, and warranty coverage. Some suppliers bundle installation support, which can impact overall value.

Request detailed quotations to compare pricing on an equivalent basis. Volume discounts and long-term partnerships can reduce costs but confirm these options upfront. Transparency about pricing models signals a professional supplier.

Installation and Support Services

Reliable installation and ongoing support are essential for aluminum cladding projects. Services typically cover tailored project planning, expert technical advice during installation, and comprehensive after-sales assistance to ensure long-term performance.

Project Consultation

During project consultation, the supplier evaluates the specific needs of the building’s design, location, and intended use. This assessment includes material selection based on durability, fire resistance, and aesthetic requirements.

A detailed site analysis is conducted to anticipate challenges like weather exposure or structural limitations. Clear timelines, cost estimates, and installation logistics are provided to align expectations with client goals.

Consultants also advise on compliance with local building codes and environmental standards. This step helps prevent delays and rework, ensuring the project proceeds smoothly from start to finish.

Technical Guidance

Technical guidance involves supplying contractors and installers with precise instructions and documentation. Suppliers offer detailed installation manuals, CAD drawings, and recommended fastening methods.

They may also provide on-site supervision or training sessions to ensure correct handling and assembly. This reduces errors that could affect cladding integrity or appearance.

Guidance covers compatibility with substrates, joint sealing, and thermal expansion considerations. Assistance in integrating air barrier systems or drainage planes often forms part of the support.

Clear communication between the supplier and installation team is maintained to address issues in real-time, minimizing downtime and warranty risks.

After-Sales Support

After-sales support focuses on maintaining performance and addressing any concerns post-installation. This includes warranty management, inspection services, and troubleshooting assistance.

Suppliers often offer routine maintenance advice, such as cleaning procedures and damage prevention tactics. They may also provide replacement parts or repair services if required.

Clients receive technical support channels for quick resolution of issues like panel warping or sealant failure. Keeping detailed records of service history helps anticipate lifecycle costs and optimize cladding longevity.

This ongoing support protects the investment and preserves the aesthetic and functional qualities of the aluminum cladding system.